| Specialist measurement services, from a team you can trust |

Non-contact video monitoring service

– Smart, Safe and Efficient –

Imetrum Dynamics provides a non-contact vision based monitoring service for civil and industrial applications.

Based upon Imetrum’s globally established Dynamic Monitoring System (DMS) technology and Video Gauge™ software the service is delivered by a team of experienced Imetrum engineers.

Imetrum’s video monitoring service brings a cost efficient solution for accurate, real time dynamic data capture, which is further supported and enhanced by full post process capability.

DMS and Video Gauge™ is Imetrum’s proprietary technology which enables our engineering team to adapt and develop specialised solutions to meet demanding monitoring requirements.

Flexible, time efficient and capable

DMS and Video Gauge™ is best suited for short term dynamic events such as passing traffic, industrial processes, load tests and forced vibrations. However longer term monitoring campaigns can be undertaken with appropriate considerations.

The ability to monitor dynamic behaviour from distance, often without physical contact of the asset, reduces monitoring cost and personal risk. This can prevent the need for closure permissions or interruption to industrial operations.

Typical data delivery includes displacements, strains, vibrations, and rotations, which can be supplied in traceable tabulated format. Our dynamic datum capability can isolate specific movements in complex systems.

It is recommended that our team assist in designing monitoring schedules to ensure the video technology is deployed effectively and delivers the required data.

Typical use cases

Bridges

Buildings

Industrial processes

Rail track and track bed

Overhead electrified line

Civil structures

Tunnels

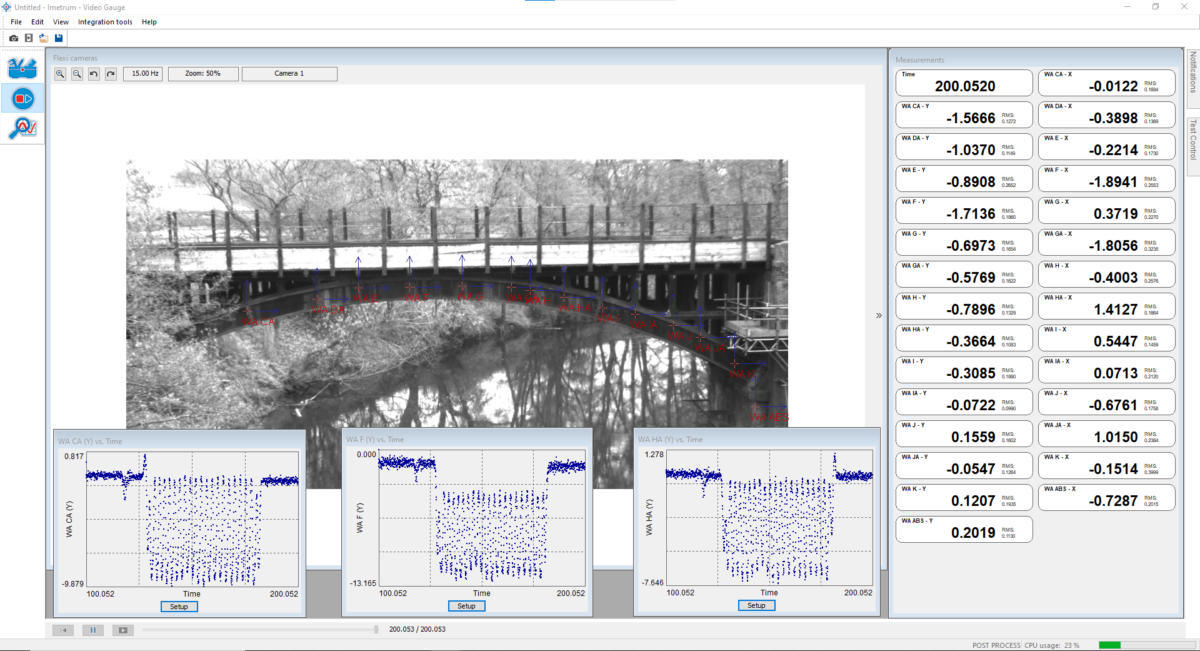

Dynamic Bridge Monitoring

The dynamic response to passing live traffic or pre arranged load tests can be captured in real time, often without direct access to the measurement locations.

Multiple cameras can be deployed to capture different features simultaneously. High sampling rates enable highly dynamic monitoring with sub mm resolution.

Monitoring can be completed in daylight hours or at night with appropriate lighting solutions.

Click here for the demonstration video

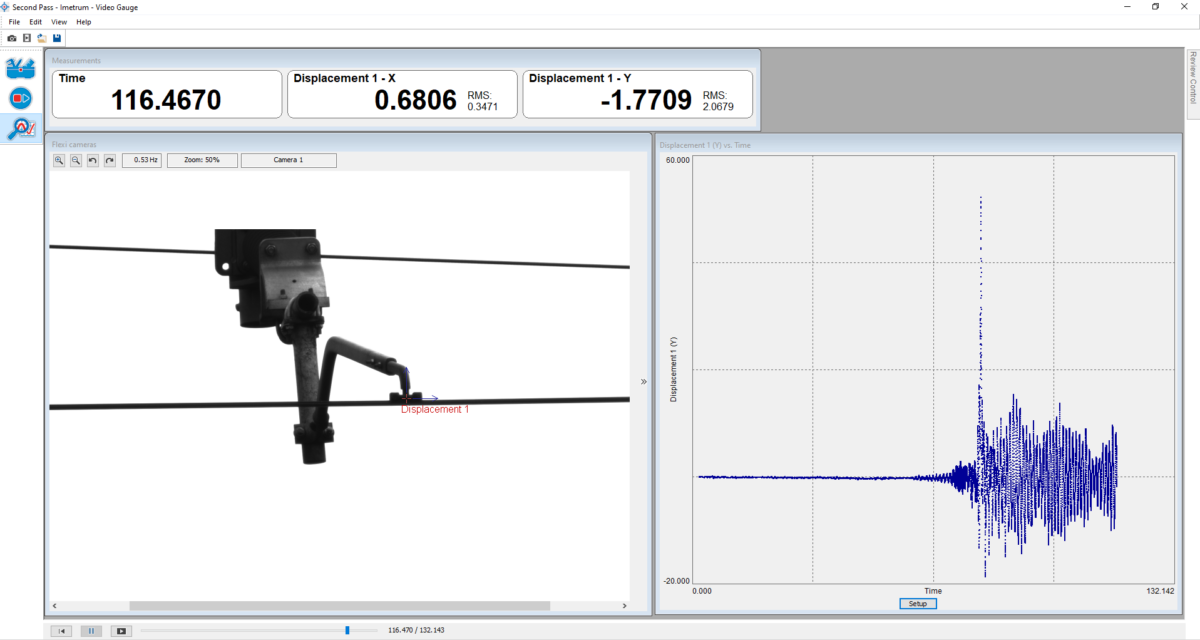

Overhead Electrified Line

Real time, dynamic overhead electrified line uplift can be measured from a position of safety without the need to go track side.

High data capture rates enable uplift to be measured at rail speeds of 100mph and above.

The Imetrum team have the capability of completing this monitoring during daylight hours or at night by the use of tightly controlled light sources. Resolutions of sub mm are routinely achieved.

Click here for demonstration video

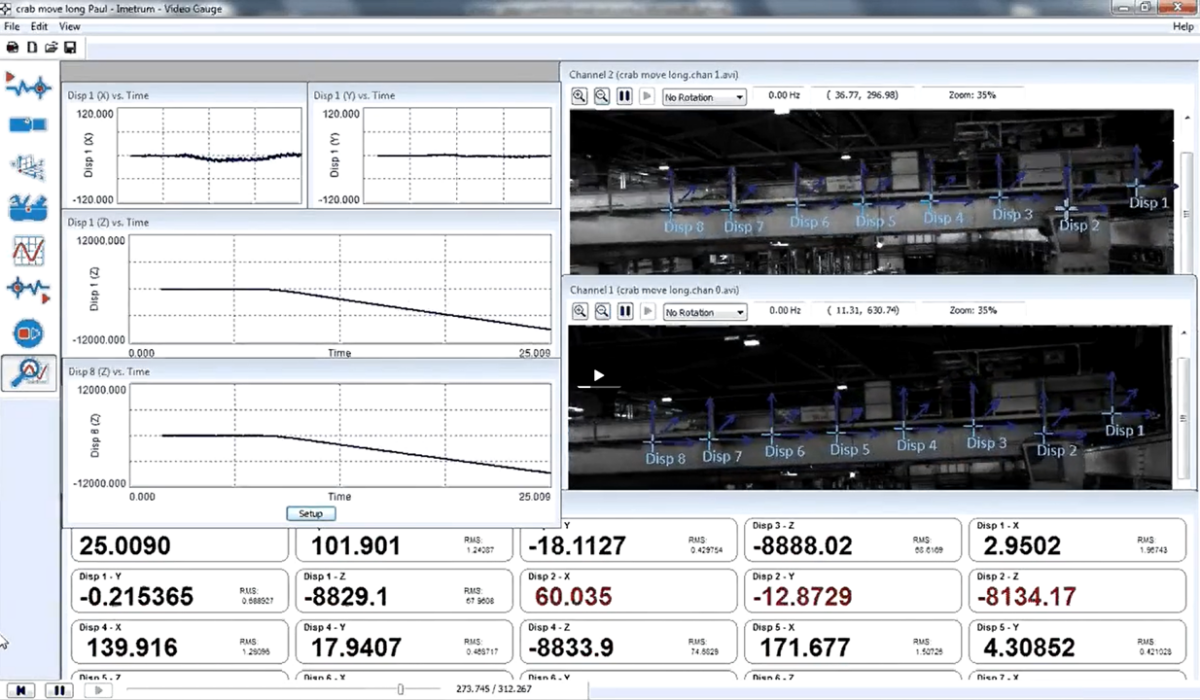

Industrial Process

Overhead gantry crane – alignment and load testing and validation – In development

Click here for demonstration video

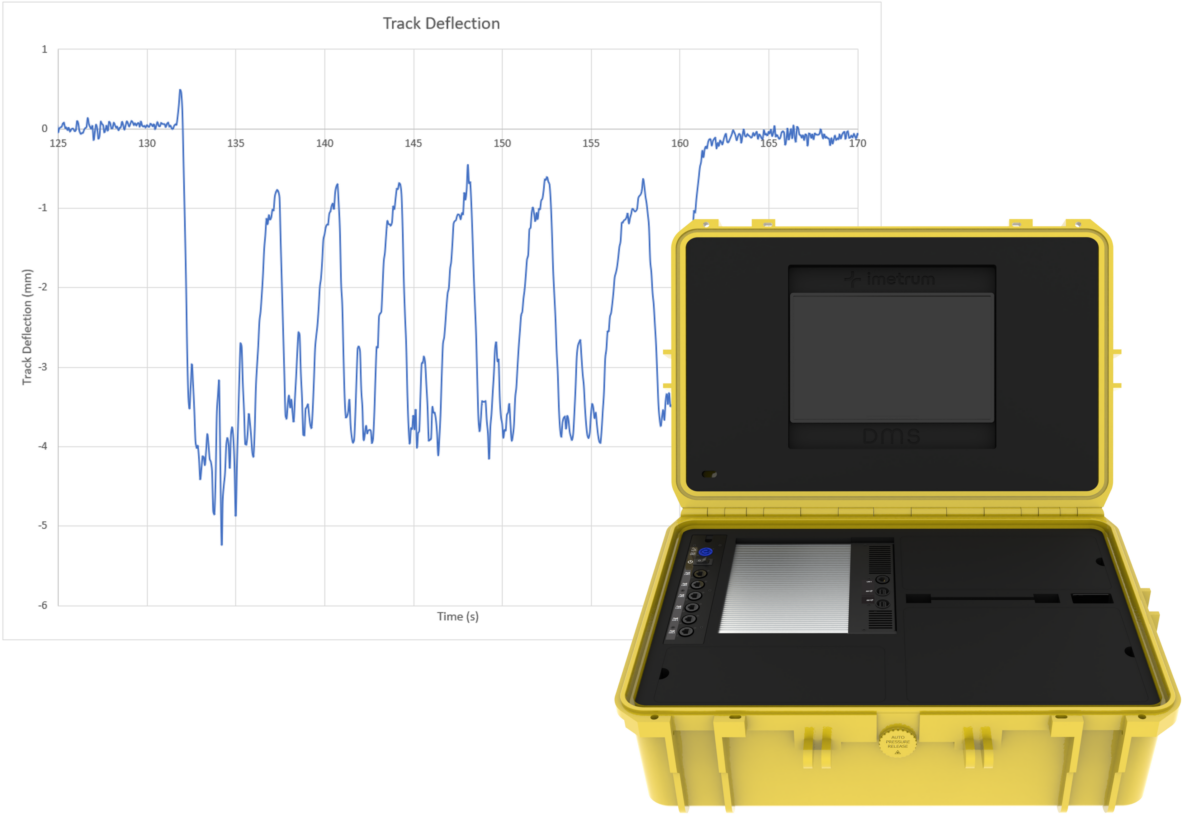

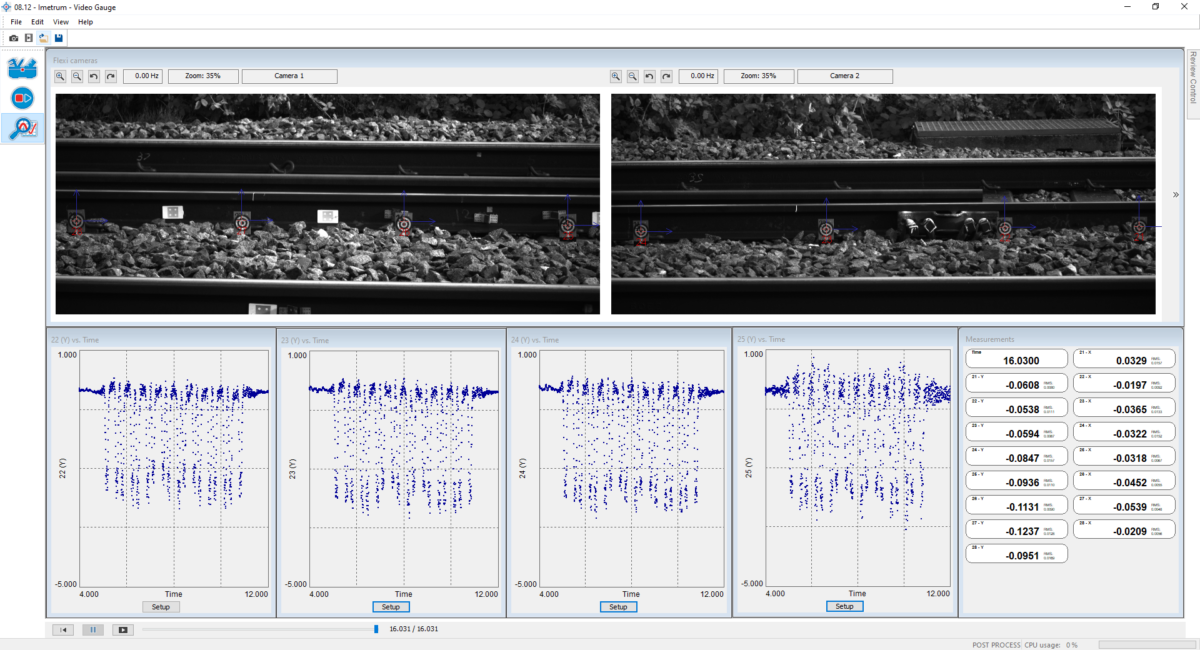

Rail Track Displacement

Track bed stiffness calculations require a direct measurement of rail rack deflection under a live load.

Imetrum’s DMS technology can resolve individual axles passing over individual sleepers, joints or fish plates.

When it is not possible to mark the rail track, natural features such a bolts or clips can be used to to obtain measurements with sub mm resolution

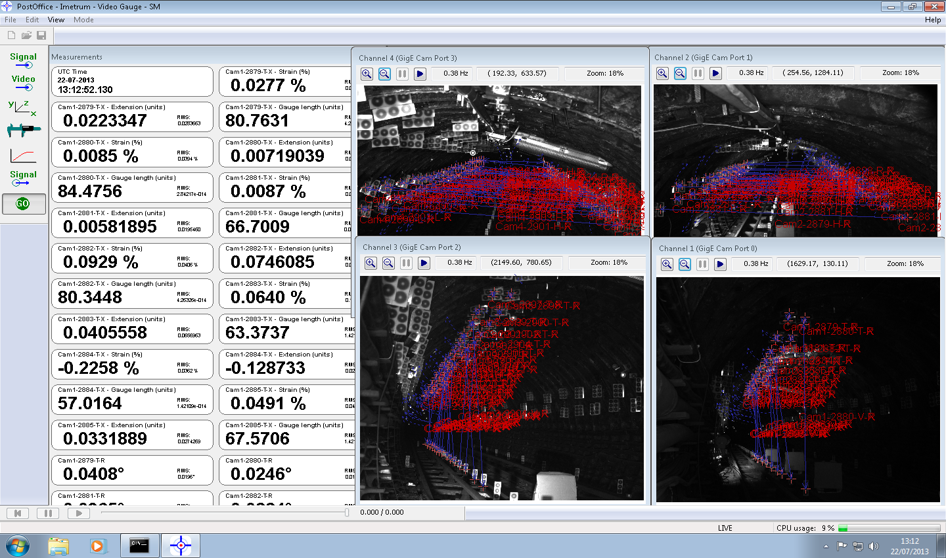

Tunnel Convergence

The controlled environment of a tunnel enables DMS to be deployed for longer term monitoring. Convergence and dimensional changes can be monitored over weeks and months to resolution of 0.1 mm or better.

Have some questions?

Just speak to a member of the Imetrum team.